CELL INSTRUMENTS

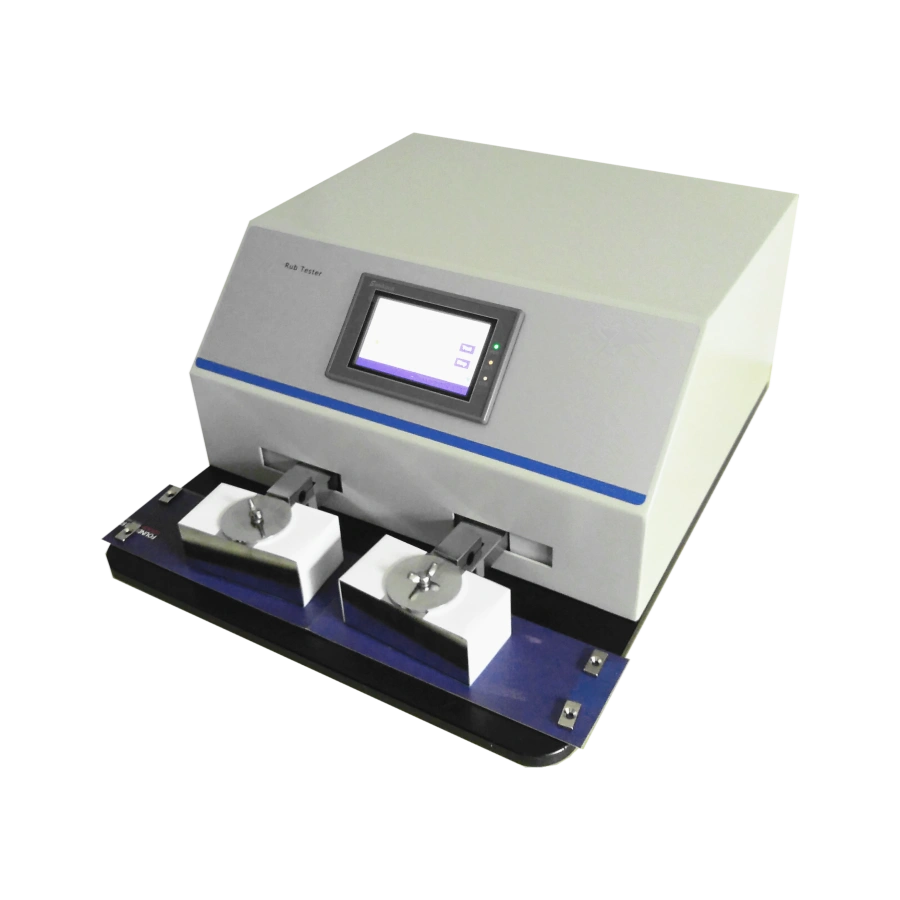

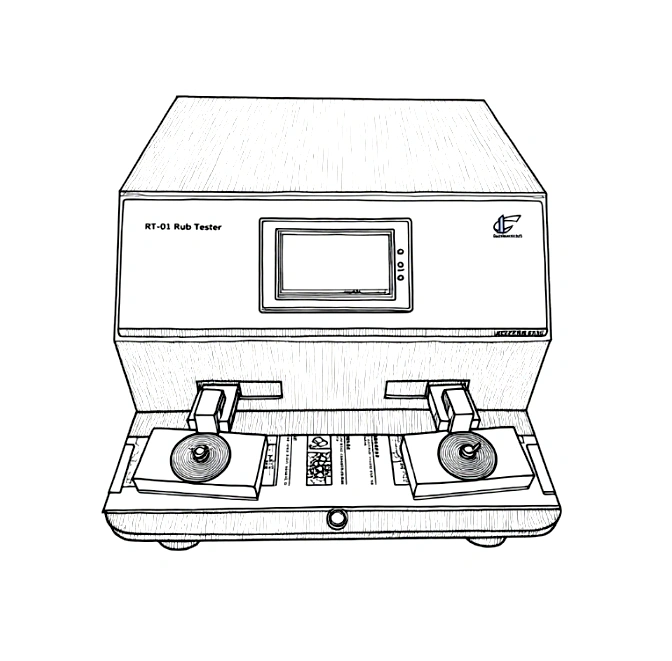

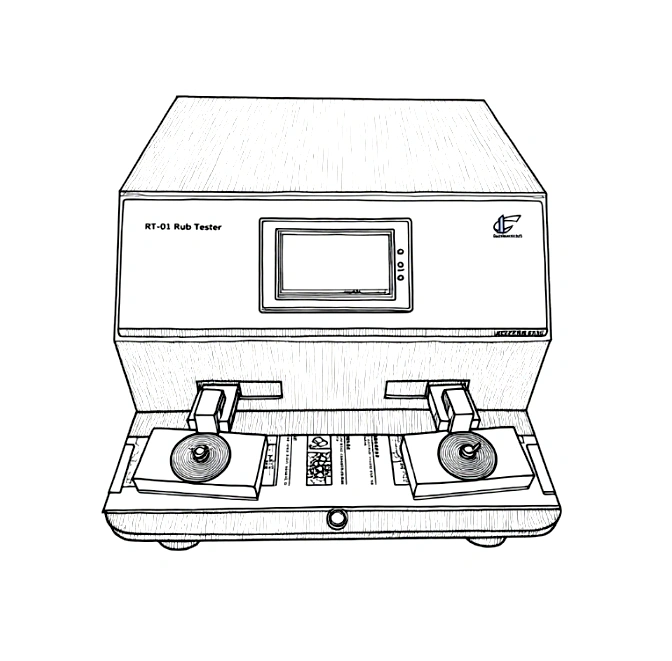

Ink Abrasion Resistance Tester

Ink Rub Standards

ASTM D5264, TAPPI T830

Technical Specifications

| Rub Pressure | Rub Speed | Rub Mode | Rub Times | Number of Specimens | Power Supply | Instrument Dimension | |

| 8.9 N(2lb); 17.8N(4lb) | 20~120 cpm free setting | Arc Reciprocating Movement | 0 ~ 999999 | 1 ~ 2 | 110~220V 50/60Hz | 390 mm (L) x 480 mm (W) x 220 mm (H) | |

Principle

- Friction control: The friction is controlled by an electronic weighing sensor. The user can set the range and maintain constant pressure to ensure test consistency.

- Friction motion simulation: The friction head moves along the surface of the sample, with adjustable speed (1-300 mm/min) and stroke (0-100mm) to simulate different friction scenarios.

- Multi-mode testing: Supports dry friction, wet friction, ink shedding, label discoloration and other tests to meet the needs of different materials.

- Data collection and analysis: Real-time recording of friction and speed, export of data via USB for easy analysis.

- Result evaluation: Evaluate the wear resistance and friction coefficient of the material through data such as friction and speed.

Test the abrasion resistance of printed ink or coating

Testing Applications

01

Packaging and printing

Used to verify the wear resistance and pattern shedding of printed materials, especially for products such as packaging bags, labels and cartons.

02

Label and barcode

Test whether labels are easy to fall off due to friction during actual use to ensure the integrity of labels under long-term use.

03

Paper

For different types of paper, Rub Tester can provide comprehensive friction tests to ensure the stability and durability of the paper surface during processing.

03

Cosmetic and consumer product packaging

Test the wear resistance of bottle screen printing, labels, packaging films, etc. to ensure their visual effects and quality durability during use.

RT-01 Ink Abrasion Resistance Tester

RT-01 friction tester can simulate the friction conditions in actual use by precisely controlling the test parameters such as friction force, speed, and pressure, helping users to accurately evaluate the friction performance and wear resistance of materials. While ensuring the test accuracy, it provides flexible test modes and a wide range of applications. It is widely used in packaging, printing, paper, labels and other industries, providing strong technical support for enterprises in material selection and quality control.

Digital Ink Rub Tester

RT-01 Ink Abrasion Resistance Testing Importantce

Ink Abrasion Resistance Tester

Importantce

The application of RT-01 friction tester not only optimizes product quality, but also provides precise support in R&D and production. It is a key tool to ensure product quality and market success.

Ensure product quality

By accurately testing the friction performance of materials, RT-01 helps ensure the wear resistance of products in actual use and reduce quality problems caused by friction, such as print pattern peeling, label discoloration, etc.

Improve production efficiency

The automated testing process reduces manual intervention, improves testing speed and data accuracy, and makes quality control more efficient and reliable.

Meets Industry Standards

The RT-01 complies with international standards such as ASTM and TAPPI, ensuring test results have industry-recognized accuracy, helping companies meet regulatory requirements.

Optimize material selection and process

Accurate friction coefficient and wear resistance data can provide a scientific basis for material selection and production process optimization, reducing production costs and scrap rates.

Enhance market competitiveness

Through reliable friction test data, companies can improve product consistency and reliability, enhance consumer trust, and thus improve market competitiveness.

Cell Instruments Advantages

1.Professional manufacturer background

With many years of R&D and production experience, we focus on packaging, medicine, food, and electronics. We have a strong R&D team and modern manufacturing system to ensure leading product quality and technical level.

2.Strong custom development capabilities

With deep technical accumulation, we provide tailor-made solutions, including function adjustment, software customization, and automation transformation, to flexibly respond to various testing needs and improve testing efficiency.

3.Complete after-sales service system

With a technical support and after-sales service network covering the national and overseas markets, we provide full-service services such as operation training and remote diagnosis to ensure that customers are worry-free and minimize downtime.

ASTM D5264 for Inks

Frequently asked questions

Q1: Can Rub Tester support friction testing of different materials?

A1: Yes, Rub Tester is designed with multiple test modes (such as dry friction, wet friction, ink shedding, label discoloration, etc.), which can be widely used in friction performance testing of different materials, such as paper, labels, films, printed materials, etc.

Q2: Are the test results of the equipment accurate?

A2: Since Rub Tester is equipped with high-precision sensors and closed-loop control systems, the results of each test are ensured to be stable and repeatable. The test data can be exported via USB for further analysis.

Q3: How to calibrate and maintain the equipment regularly?

A3: We provide annual inspection and calibration services for equipment. Customers can make appointments for regular maintenance through the official website to ensure that the equipment is always in the best working condition. Professional technicians will come to the door every year to perform equipment inspection and calibration.

Q4: What are the main advantages of using Rub Tester?

A4: Rub Tester provides high-precision, multi-mode friction performance testing to help companies improve product quality consistency and avoid product returns or quality complaints caused by friction performance problems. It is particularly suitable for packaging, printing, paper, labels and other industries.

Get in touch

No. 5577 Gongyebei Rd, Licheng, Jinan, 250109, Shandong, P.R.C.

marketing@celtec.cn

+86 185 6001 3985