The Sutherland Rub Test ASTM is a critical quality control method used to evaluate the abrasion resistance of printed materials, particularly in packaging, labeling, and other surface-printed products. As print durability becomes increasingly important across industries—especially in food, pharmaceutical, and consumer goods sectors—understanding this test method is essential for quality assurance professionals and manufacturers alike.

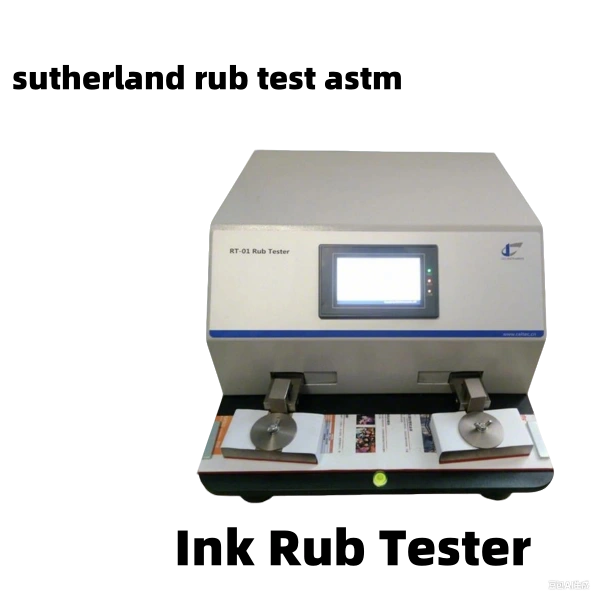

This article explores the Sutherland Rub Test ASTM, elaborates on the ink rub test procedure, and explains the role of the Ink Rub Resistance Tester in maintaining product integrity. We will also introduce the Cell Instruments RT-01 Ink Rub Resistance Tester, a reliable solution for consistent and accurate rub resistance evaluations.

What Is the Sutherland Rub Test ASTM?

The Sutherland Rub Test, as outlined in ASTM D5264, is a standardized method to assess the rub resistance of printed surfaces. It determines how much ink or coating is transferred or worn away when subjected to repeated rubbing under controlled pressure and speed. This test is widely used in evaluating labels, folding cartons, flexible packaging films, and other printed substrates.

The core principle of this test lies in the controlled friction between two surfaces—usually a printed sample and a reference surface (either unprinted or similarly printed). The test replicates the abrasion and scuffing that printed materials may face during handling, transport, and storage.

Importance of Ink Rub Resistance Testing

Ensuring print quality isn’t just about aesthetics—it’s also about preserving critical information, such as barcodes, lot numbers, usage instructions, and branding. Smudging or ink degradation can lead to product recalls or regulatory non-compliance.

Implementing Sutherland Rub Test ASTM in your quality control processes can help:

- Validate ink adhesion and resistance

- Improve print process parameters

- Identify subpar coatings or finishes

- Ensure compliance with industry standards

Ink Rub Test Procedure: Step-by-Step Overview

Understanding the ink rub test procedure is vital for generating repeatable and consistent results. Below is a generalized workflow based on ASTM guidelines and practical laboratory practices:

- Sample Preparation

Cut samples to the specified size. One surface should have the printed area to be tested. - Weight Selection

Choose the appropriate test weight (commonly 2 or 4 pounds), depending on substrate type and required pressure. - Cycle Setting

Set the number of rub cycles. Most standards recommend 10 to 100 double rubs, but this can vary depending on test goals. - Mounting

Secure the sample and the test strip (or receptor surface) on the tester’s base and rubbing head, respectively. - Test Execution

Initiate the test. The Ink Rub Resistance Tester simulates uniform back-and-forth rubbing motion under constant pressure. - Evaluation

After the test, inspect the samples for visible ink transfer, color fading, or smearing. This can be done visually or with a spectrophotometer for quantitative analysis.

Choosing the Right Ink Rub Resistance Tester

A reliable Ink Rub Resistance Tester is critical for achieving consistent results and ensuring the repeatability of the Sutherland Rub Test ASTM. The Cell Instruments RT-01 Ink Rub Resistance Tester is a highly recommended solution, offering:

- Compliant design with ASTM D5264 and TAPPI T830

- Adjustable load for multiple substrate types

- Digital control panel with preset cycle settings

- Stable mechanical design to reduce vibrations and human error

The RT-01 is ideal for laboratories and production lines seeking to enhance print quality assurance through accurate rub resistance measurement.

Applications Across Industries

The Sutherland Rub Test ASTM is applicable across a wide range of industries:

- Pharmaceutical Packaging: Ensure dosage info and expiry dates remain readable

- Food and Beverage Labels: Prevent branding and regulatory info from smudging

- Consumer Electronics: Maintain clarity of logos and technical labeling

- Textiles and Flexible Films: Test printed fabrics or multilayer packaging films

By incorporating rub resistance testing into your QA processes, you reduce product failure risks and boost brand reliability.

Why Choose Cell Instruments?

Cell Instruments specializes in material testing solutions for packaging, medical devices, textiles, and more. We offer not just precision instruments but tailored solutions, automation services, and expert technical support to meet your rub resistance testing needs.

The RT-01 Ink Rub Resistance Tester exemplifies our commitment to innovation, compliance, and user-friendliness—ensuring your printed materials meet the highest durability standards.

Conclusion

The Sutherland Rub Test ASTM is indispensable for validating the durability of printed materials under real-world conditions. With a clear ink rub test procedure and the right Ink Rub Resistance Tester, manufacturers and QA teams can ensure compliance, reduce risks, and enhance customer satisfaction. For advanced, reliable testing, consider integrating the Cell Instruments RT-01 into your lab.